Auto Feeding Systems

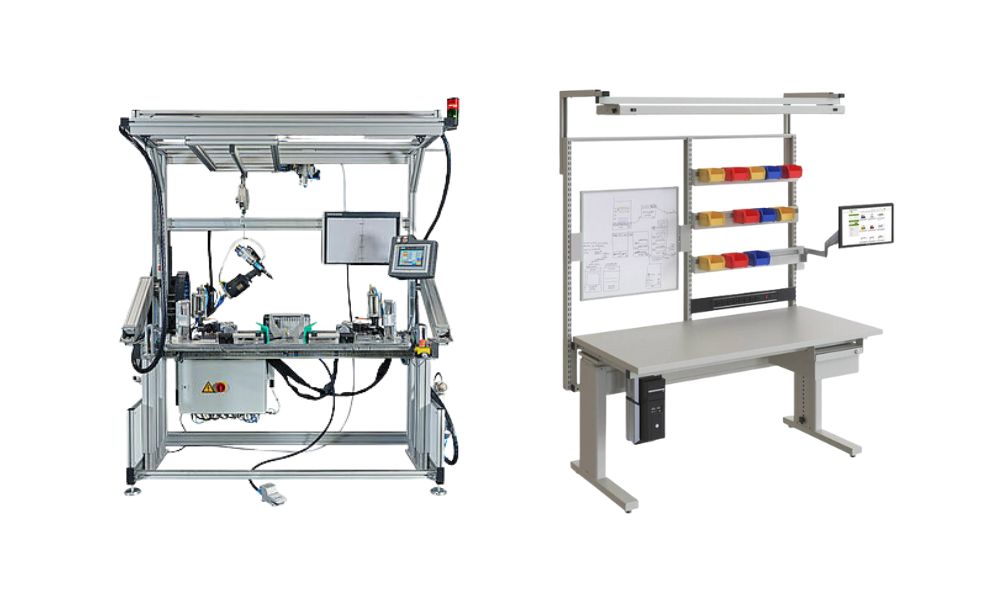

Logicontrol's Auto Feeding Systems are designed to automate the precise and consistent feeding of parts, materials, and components into production lines. By eliminating manual handling, these systems improve productivity, reduce errors, and ensure smooth, uninterrupted operations. Built with advanced sensors, intelligent controls, and robust mechanisms, our feeding solutions are tailored to meet diverse industry requirements.

Our auto feeding solutions are widely used in industries where high-speed, repeatable, and accurate part orientation is critical, including automotive, electronics, pharmaceuticals, packaging, and consumer goods. Each system is engineered to seamlessly integrate with assembly lines, rotary indexing systems, and robotic automation setups.

Key Features

-

Consistent and accurate part feeding for uninterrupted operations

-

Customizable bowl, linear, and flexible feeders to match components

-

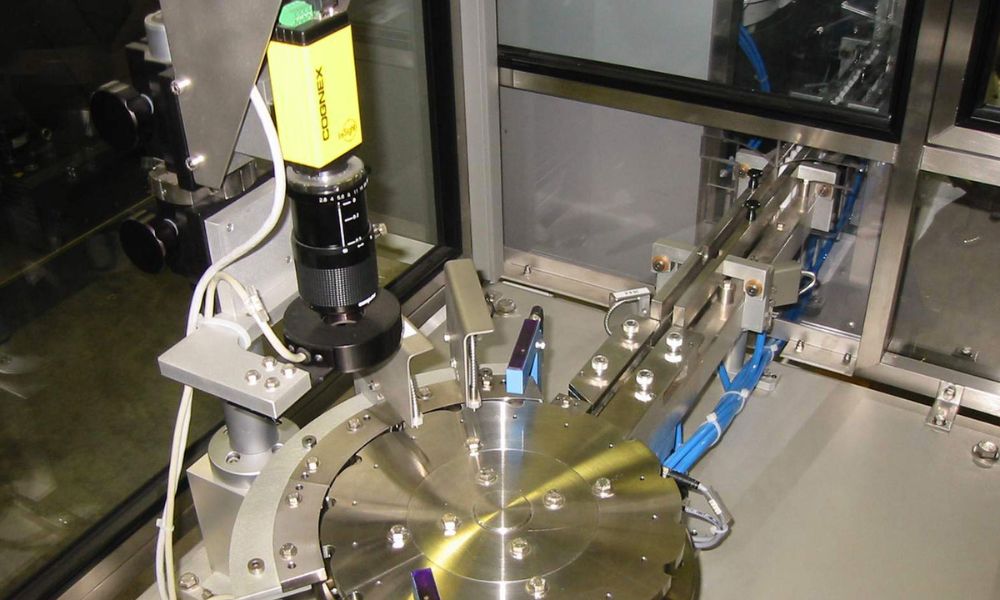

Equipped with vision-guided error detection and correction

-

Low vibration and noise levels for improved work environment

-

Compact, modular design for easy integration

Applications

-

Automotive component feeding (bolts, screws, clips, and fasteners)

-

Electronics industry for PCB component placement

-

Pharmaceutical and medical device packaging

-

Food and beverage processing and packaging

-

Plastic parts and consumer goods assembly lines

Our Specialized Auto Feeding Machines

-

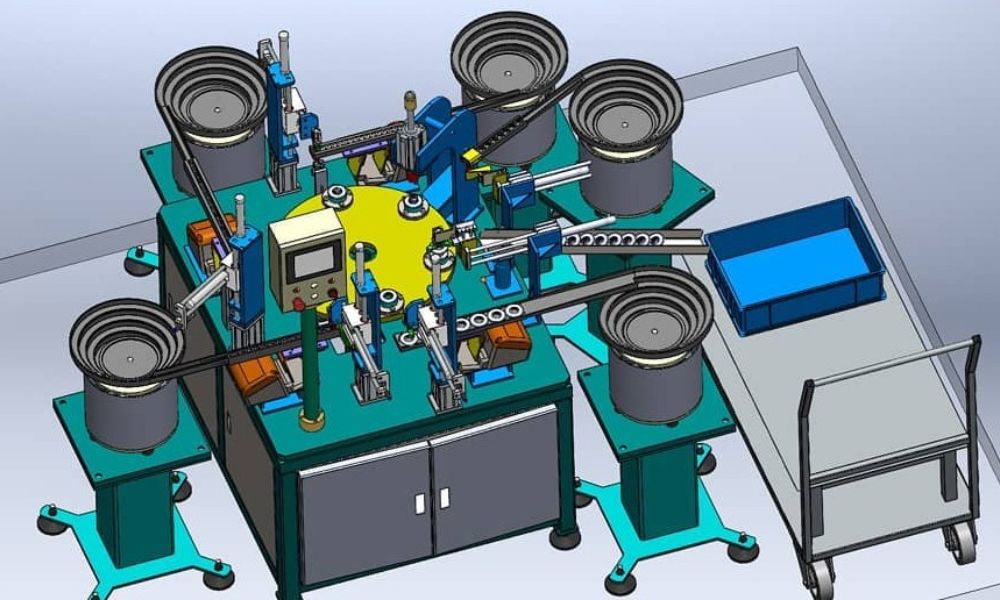

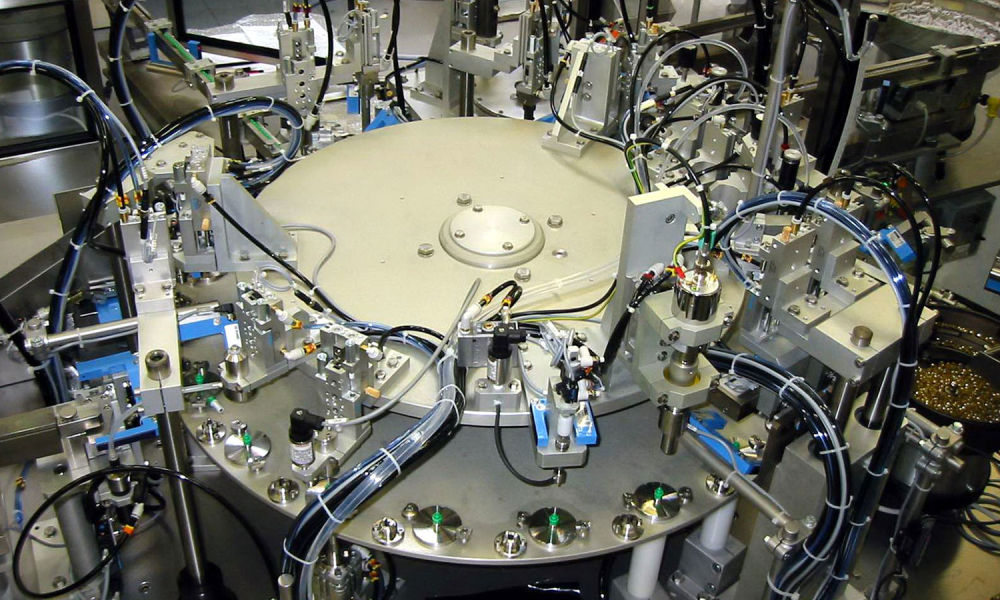

Vibratory Bowl Feeders – Reliable feeding systems that orient and deliver small components consistently for high-volume assembly lines.

-

Linear Feeders – Provide smooth, accurate, and stable transfer of parts between different process stages with high precision.

-

Flexible Feeders with Vision Systems – Advanced systems that use cameras and AI to handle parts of varying shapes and sizes without the need for retooling.

-

Rotary Feeding Systems – Ideal for compact workstations requiring continuous and synchronized part delivery to multiple stations.

Benefits

-

Higher production efficiency with reduced downtime

-

Accurate part orientation and placement

-

Reduced dependency on manual labor

-

Flexibility to handle multiple product types

-

Improved safety and ergonomics in production lines