Auto Component Assembly Systems

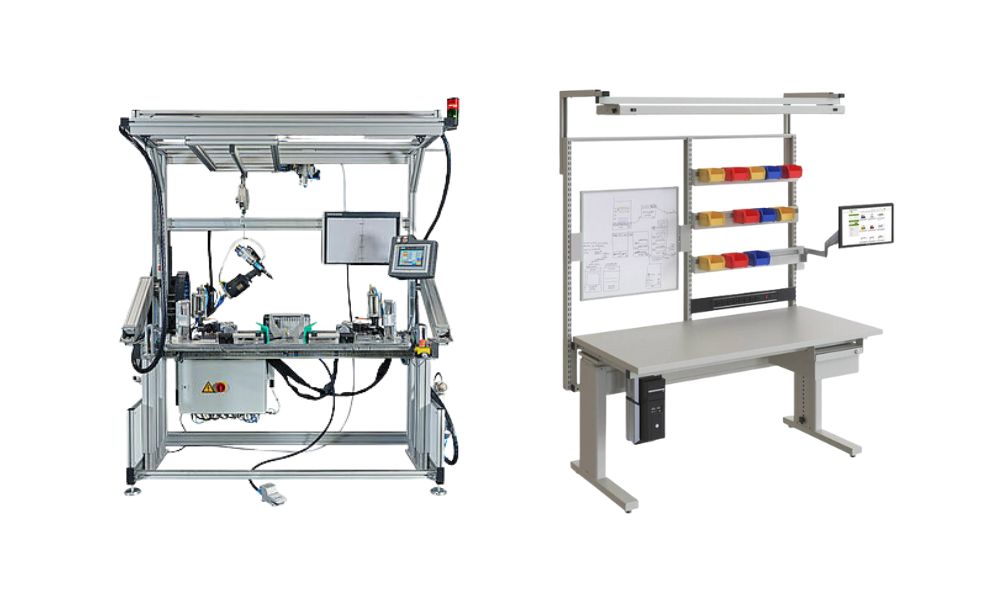

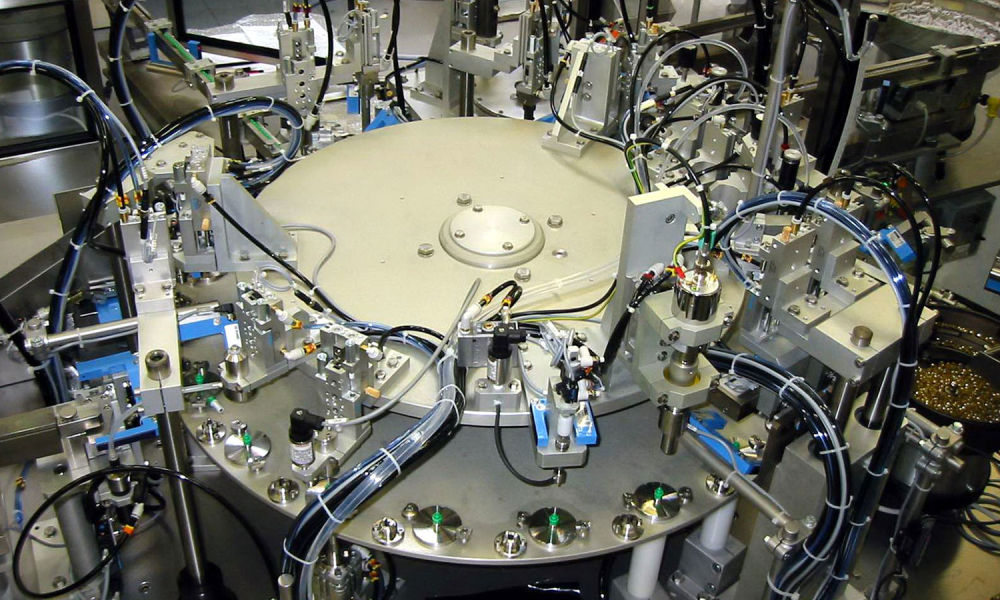

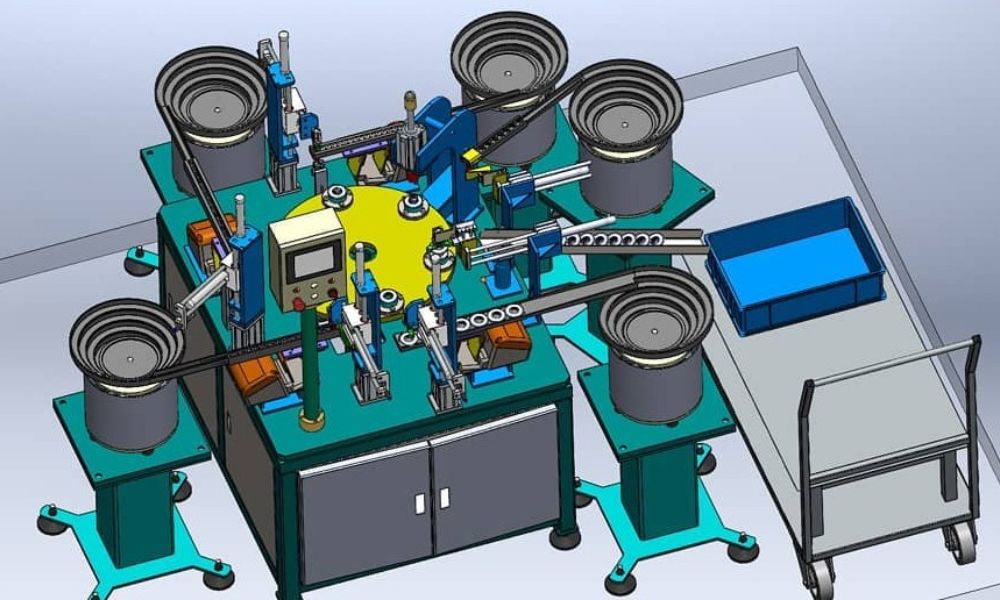

Logicontrol's Automatic Component Assembly Systems are engineered to deliver precision, speed, and consistency in modern manufacturing environments. These specialized machines automate complex assembly tasks, minimizing manual intervention while ensuring unmatched accuracy and productivity. Designed with modular and scalable architecture, our systems integrate seamlessly into production lines to optimize efficiency and reduce cycle times.

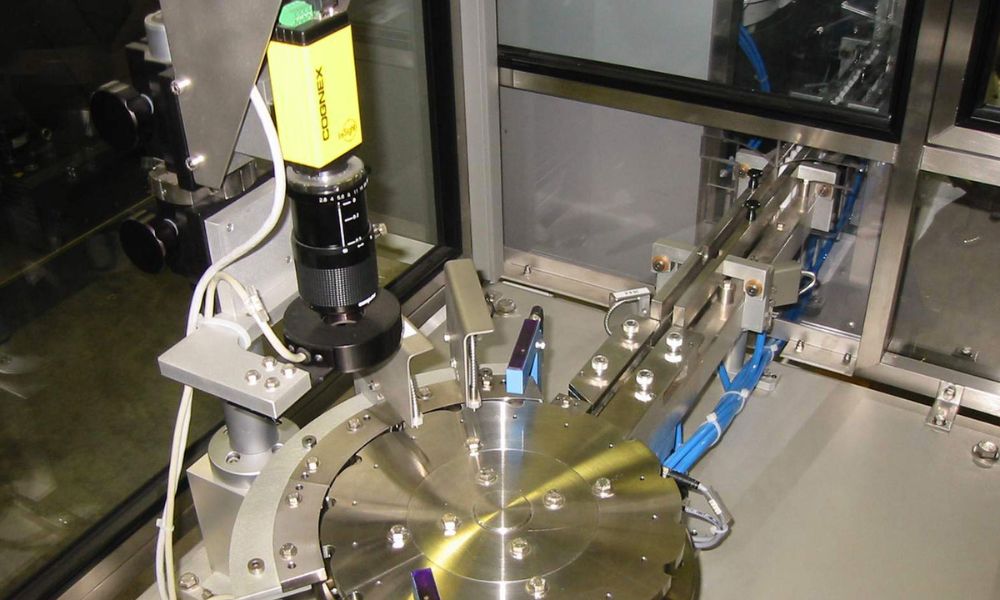

Equipped with advanced robotics, intelligent controls, and real-time monitoring, our assembly systems address the needs of industries such as automotive, electronics, medical devices, and consumer goods manufacturing. Each solution is tailored to meet specific customer requirements, helping businesses enhance competitiveness in a rapidly evolving industrial landscape.

Key Features

-

High-precision automated assembly of intricate components>

-

Flexible configurations to adapt to different product requirements

-

Smart sensors and error detection mechanisms for quality assurance

-

Compact design with seamless line integration

-

Low maintenance and energy-efficient operation

Applications

-

Automotive component assembly (engine parts, electrical modules, sensors)

-

Electronics and semiconductor assembly

-

Medical device production and packaging

-

Appliances and consumer goods assembly

-

Industrial machinery component integration

Our Specialized Assembly Machines

-

AMT Assembly Line- A fully automated modular assembly line designed for high-volume production. It ensures consistent assembly with minimal downtime and offers flexibility to handle multiple product variants.

-

Automatic Segmentation and Pasting Machine - A precision-driven system ideal for electronics and material processing industries. It performs accurate segmentation, pasting, and placement of components, ensuring superior consistency and quality.

-

Robotic Pick & Place System - High-speed robotic solution for automated handling, sorting, and assembly of delicate components with unmatched accuracy.

-

Inline Screw Tightening & Fastening Machine - Specialized for mechanical assembly operations, ensuring torque accuracy and uniform fastening for safety-critical parts.

Benefits

-

Significantly increased production speed and reduced cycle time

-

Improved product consistency with advanced error-proofing

-

Lower operational costs and minimized human dependency

-

Scalable solutions to meet future business growth

-

Enhanced global competitiveness through cutting-edge automation